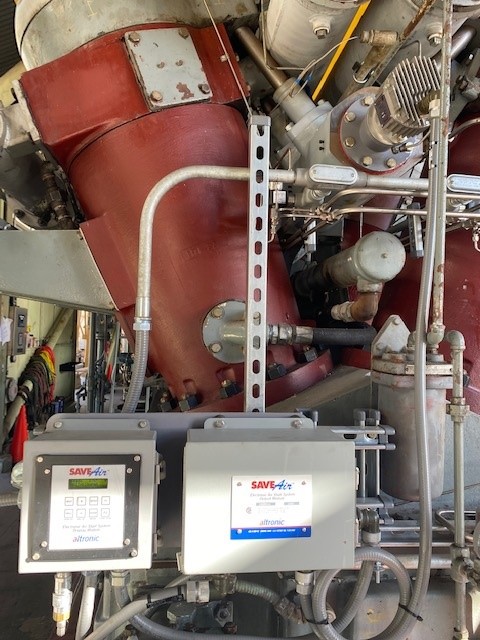

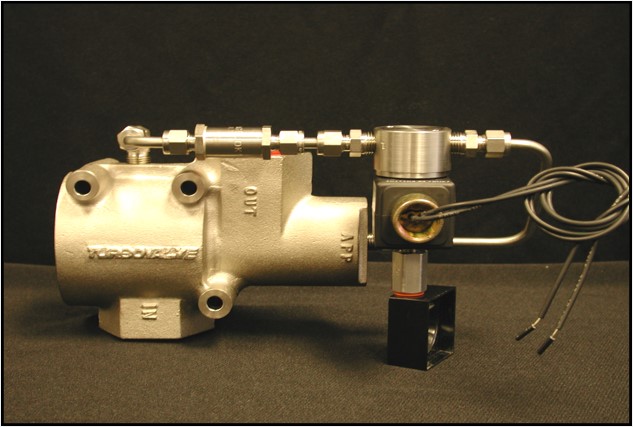

The SaveAir™ Electronic Air Start System brings solid-state electronic control to the starting function on air-in-head starterequipped integral compressor engines. Eliminating many of the mechanical air-start related components, the solid-state SaveAir system introduces significant operational advantages, including a substantial reduction in the required starting air (up to 70%) and the elimination of starting “dead spots”. The SaveAir system replaces the existing OEM or pneumatic air distributor system with an innovative position sensing device (the SaveAir Distributor) to determine the precise angular location of the engine crankshaft. Given accurate radial position data, the SaveAir system electrically actuates air-starting solenoid valves which precisely control both the turn-on time of the in-head valves as well as the duration of the air admission events during startup. These unique capabilities enable the SaveAir system to deliver starting air to those cylinders which are most appropriate given the angular position of the crankshaft — virtually eliminating engine starting “dead spots” — and to dramatically reduce the amount of air ultimately required for the engine start. The net effect of the SaveAir™ system is more reliable remote starting, improved operator safety (no mechanical barring), reduced air consumption, and more efficient compressor station operation.

Replaces existing air-in-head starting systems with solid-state microprocessor-based control technology

Reduces starting air consumption by as much as 70% per start

Eliminates “dead spots”

Eliminates manual barring of engine – increases operator safety

Provides more reliable remote starting

Eliminates failure prone mechanical air start distributor and cam actuated valves

Less costly and complex than ring-gear based starting conversion systems

“Universal” system can be installed on virtually any suitable engine

CSA certified for use in Class I, Division 2, Groups C and D hazardous areas