DE-4000 SCRIPTING REFERENCE MANUAL

There is a delicate balance between providing a system that has capabilities that can be configured through a fixed set of options, and one that can be extended and expanded with custom programming. In designing the DE-4000 control system, the choice was made to provide a system where most applications can be met with simple configuration, but advanced functionality can be provided through custom programming using the “Lua” language.

Lua is often referred to as a scripting language. Scripting languages differ from compiled languages as they eliminate extra step of compiling the written program into machine code.

Lua comes with a background of being robust, fast, and geared towards embedded applications, with a proven track record in the gaming industry. For the DE-4000 system it is small and fits in the memory we have available, holds a lot of power, and keeps it simple for writing in the language. All information regarding the Lua scripting language is located at https://Lua.org Using the Lua engine as an embedded tool allows for taking advantage of a full architecture and standard at your fingertips. Within the language there are all of the normal attributes to programming such as functions, variables, statements, expressions etc. All of this reference material can be found at https://lua.org/ manual/5.3/ For getting started and using a guided reference, there are several editions of “Programming in Lua” available. Most recent editions are a paid for product that come in paper back or ebook form. While testing out Lua and becoming familiar, a free first edition is available and covers a lot of learning needs to get comfortable with the language. It can be located at https://www.lua.org/pil/contents.html. A major advantage to using Lua is its inherent ability to allow custom functions. While all normal functions and calls are published, there is the ability to add new functions in the DE-4000 firmware. Once new functions are defined and have calls to their internal properties, they then can be published for the user. This includes functions such as our flexible Modbus table and talking with various terminal boards linked in the system. Below is the start to the list of Altronic based functions. As functionality and features come to life through new ideas, this document will continually get updated with the latest scripts that we make available.

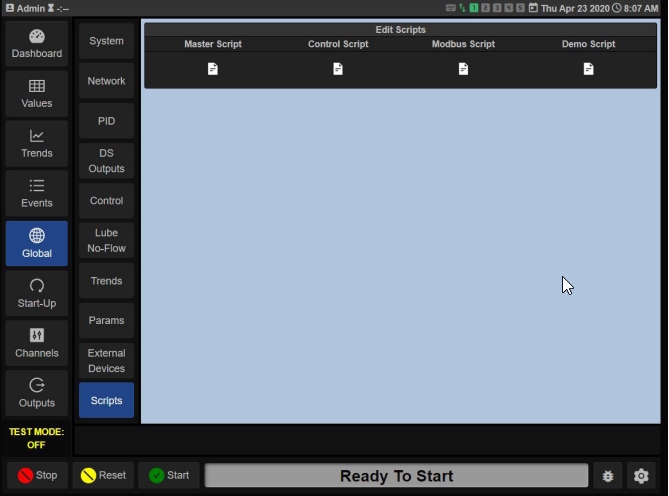

GETTING STARTED WITH DE-4000 SCRIPTS Basic Scripting on DE-4000

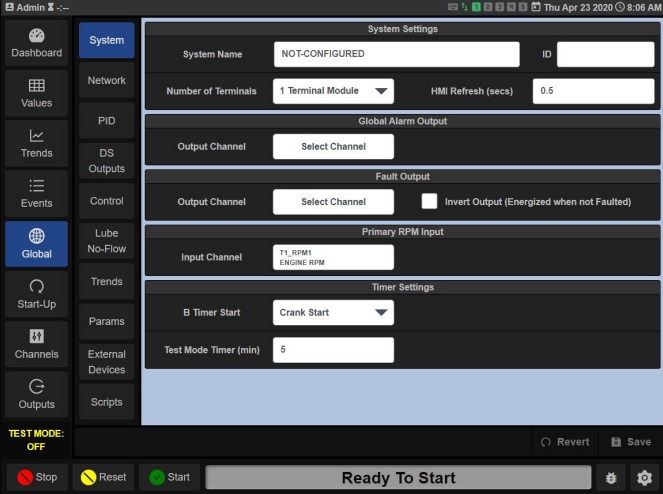

Begin on Dashboard on DE-4000 system environment

Choose “Global” from menu on left side of screen

In the Sub-Menu on the Left side select “Scripts”

Select one of the page icons under one of the 4 script options to open editor

Scripting can be entered into the editor

Scripting Windows and examples

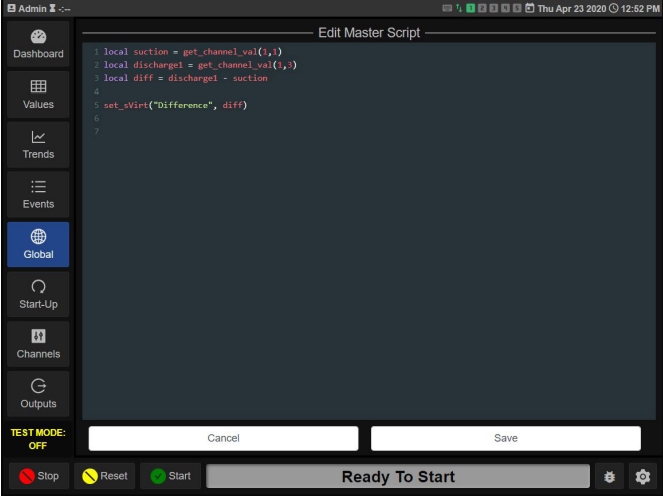

Master Script

The Master Script section is the Primary scripting environment. Primary scripting functions can be written in this section.

Example:

local suction = get_channel_val(1,1)

local discharge1 = get_channel_val(1,3)

diff = discharge1 - suction

set_sVirt(“Difference”, diff)The first line gets the channel value from Terminal board 1 Input 1 and stores it in local variable named suction. The second line gets the channel value from Terminal board 1 Input 3 and stores it in local variable named discharge1. The third line takes the discharge1 pressure and subtracts the suction pressure and stores it in the global variable named diff (NOTE: Any value that you want to access from another scripting section must be stored in a global variable. This is used most in calling values into Modbus registers as explained below). The fourth line copies the value from diff and stores it into the Virtual status channel named “Difference” This channel can be displayed on the Dashboard.

Control Script

The Control Script section is used to override the default control strategy found on the Global/Control page. A copy of the default control script (found in attached appendix) can be copied into this section and then modified to change the control functionality as well as add additional control loops beyond the default 2.

Modbus Script

The Modbus Script section is used to move data into and out of Modbus registers

defaultModbus()

set_modbus(300,diff)The first line pulls in the factory set Modbus mapping The second line moves the value from the global variable named diff into the 40300 Modbus Register

DE-4000 Lua Script API

CUSTOM FUNCTIONS FOR SCRIPTING

create_param(“index”,default,”catergory”,”description”)

-

creates a user configurable parameter

-

parameter is stored as

index, -

default value(If not changed by user) is

default -

parameters will be grouped on the Global/Params page by

category -

descriptionis text to describe the parameter to the user

Example:

create_param("NumEngCyl",8,"Engine Params","Num. of Engine Cylinders")

get_channel_val(terminal,channel)

-

returns current value of analog input

channelon terminal moduleterminal -

return value type is numeric

Example:

local sp = get_channel_val(1,5)

reads value of Suction Pressure from Terminal Module #1 , Input #5get_gbl(“index”,default)

-

returns global config setting stored under

indexor returnsdefaultif not definednote: get_gbl is used to retrieve global CONFIGURATION settings that are typically set when the system is configured and do not change as the system is running. If you want to set and retrieve global STATUS variables use the get_sGbl() and set_sGbl() functions >If you want to create and read virtual channels use the set_sVirt() and get_sVirt() functions.

Example:

local nt = get_gbl("NumTerm",1)

gets the number of terminal boards installed in the system

get_param(“index”)

-

return either the default value or the user configured value of the parameter

index

Example:

get_param("NumEngCyl")

>gets the configured parameter for number of engine cylinders

get_rpm(channel)

- reads the RPM input

channelin units of revolutions per minute

note: valid channel numbers are 1 – 10(2 channels per board, up to 5 terminal boards)

Each Terminal Module has 2 RPM inputs (RPM1 and RPM2)

-

Terminal Module #1 RPM channels are 1,2

-

Terminal Module #2 RPM channels are 3,4

-

Terminal Module #3 RPM channels are 5,6

-

Terminal Module #4 RPM channels are 7,8

-

Terminal Module #5 RPM channels are 9,10

Example:

local engineRPM = get_rpm(1)

local turboRPM = get_rpm(6)Read RPM1 channel from terminal module #1 and read RPM2 channel from Terminal module #3

get_sGbl(“index”, default)

-

If

indexis defined in the global status table then it returns the value associated withindex -

If

indexis not defined and optionaldefaultis provided then returnsdefault

>note: It is recommended to always provide a default value when using this function

Example:

local cp = get_sGbl("calculatedPressure",0)

get the previously stored value “calculatedPressure”, Returns

0if not found.

get_state()

-

returns the current engine state(possible values currently 0 – 10)

Example:

local engineState = get_state()

if engineState > 7 then

set_timer("WarmupTimer",1000)

end

get_sVirt(“index”)

-

returns the value of virtual channel

indexor returnsdefaultif the virtual channel does not exist.

Example:

local tl = get_sGbl("timeLimit")

local et = get_sVirt("ElapsedTime",0)

if et > tl then

set_sGbl("timeExceeded",true)

else

set_sGbl("timeExceeded",false)

endGets the value of virtual channel ElapsedTime and set value of status global “timeExceeded” if ElapsedTime is greater than status global “timeLimit”

get_time()

-

returns the UNIX “epoch” time (Defined as the number of seconds elapsed since Jan 1, 1970)

Example:

local startTime = get_sGbl("startTime",0)

if startTime == 0 then

local currentTime = get_time()

startTime = currentTime

set_sGbl("startTime",currentTime)

end

local et = get_time() - startTime

set_sVirt("ElapsedTime",et)Stores current time if first time through, otherwise calculate elapsed time

get_timer(“index”)

-

returns 1 or 2 values

-

First return value(Boolean) is true if timer is active(counting down) or false if timer is expired or has not been set yet

-

Second return value is the number of seconds remaining or -1 if timer is not active or has not been set yet

Example:

if not get_timer("myTimer") then

set_sGbl("timedOut",true)

else

set_sGbl("timedOut",false)

endif timer is expired, then set global status “timedOut” to true

local active,remaining = get_timer("myTimer")

if not active then

set_sVirt("timeRemaining","Expired")

else

set_sVirt("timeRemaining",remaining)

endgetStateLabel(state)

-

return the label for the engine state corresponding to the parameter

state

Example:

local stateLabel = getStateLabel(get_state())

local active, remaining = get_timer("myTimer")

if remaining > 0 then

stateLabel == StateLabel.." "..remaining

end

set_sVirt("Countdown",stateLabel)set_sGbl(“index”,value)

-

store

valuein the global status table underindex -

value can be a number or string but if storing a boolean use the tostring() function

Example:

local mpe = false

local sp = get_channel_val(1,5)

if sp > 15 then

mpe = true

end

set_sGbl("minPressureExceeded",tostring(mpe))store boolean value minPressureExceeded

set_sVirt(“index”,value)

-

sets a virtual status channel with channel name

indexNote: Once you create a virtual channel, you can add that channel to the dashboard using the channel name

index

Example:

local sp = get_channel_val(1,5) --suction pressure

local dp = get_channel_val(1,6) --discharge pressure

local diffPress = dp - sp

set_sVirt("SuctDischDiff",diffPress)calculate the differential between suction and discharge pressure and assign to virtual channel

set_timer(“index”,secs)

-

activate timer

indexand set countdown time tosecs

Example:

set_timer("myTimer",300)

create timer

myTimerand start countdown time to 300 seconds

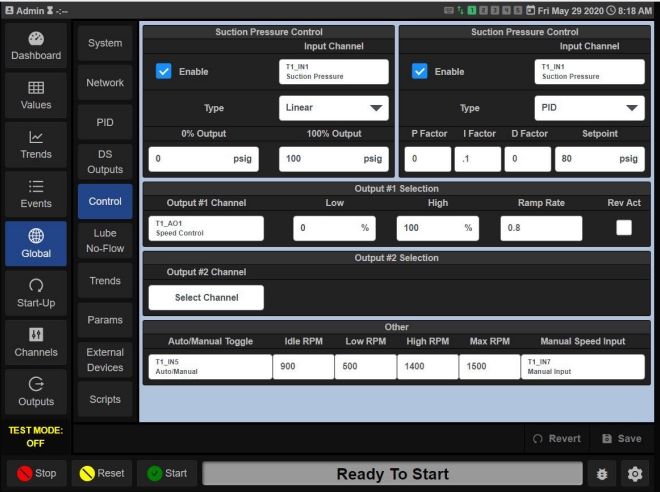

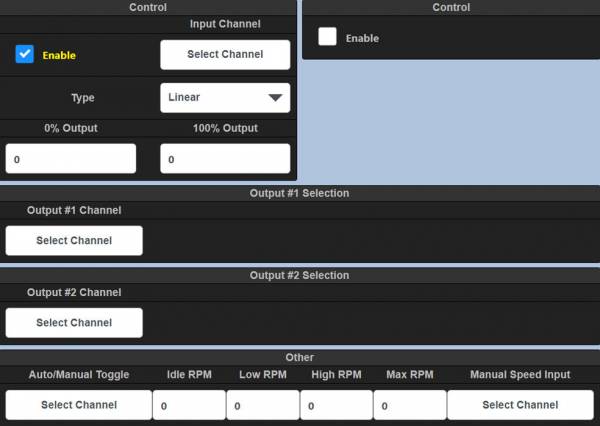

Master Control Script

When you enter a control setup under the Global Control page the code that runs is called MasterControl.

If you wish to modify this functionality you can copy this code into the Control Script editor and make your changes to the standard configuration.

local rampRate1 = get_gbl("rampRate1",0.8)

local rampRate2 = get_gbl("rampRate2",0.8)

local dischTerm = tonumber_def(get_gbl("spDischTerm",0),0)

local dischChan = tonumber_def(get_gbl("spDischChan",0),0)

local suctTerm = tonumber_def(get_gbl("spSuctTerm",0),0)

local suctChan = tonumber_def(get_gbl("spSuctChan",0),0)

local suctMin = tonumber_def(get_gbl("suctMin",0),0)

local recycleMin = tonumber_def(get_gbl("recycleMin",0),0)

local recycleMax = tonumber_def(get_gbl("recycleMax",0),0)

local suctSp = tonumber_def(get_gbl("suctSp",0),0)

local dischMax = tonumber_def(get_gbl("dischMax",0),0)

local dischSp = tonumber_def(get_gbl("dischSp",0),0)

local outputTerm = tonumber_def(get_gbl("outputTerm",0),0)

local outputChan = tonumber_def(get_gbl("outputChan",0),0)

local recycleTerm = tonumber_def(get_gbl("outputTerm2",0),0)

local recycleChan = tonumber_def(get_gbl("outputChan2",0),0)

local speedRevAct = tonumber_def(get_gbl("speedRevAct",0),0)

local recycleRevAct = tonumber_def(get_gbl("recycleRevAct",0),0)

local outputLow = tonumber_def(get_gbl("outputLow",0),0)

local outputLow2 = tonumber_def(get_gbl("outputLow2",0),0)

local outputHigh = tonumber_def(get_gbl("outputHigh",0),0)

local outputHigh2 = tonumber_def(get_gbl("outputHigh2",0),0)

local spSuctType = get_gbl("spSuctType","linear")

local spDischType = get_gbl("spDischType","linear")

local suctPIDPFactor = tonumber_def(get_gbl("suctPIDPFactor",0),0)

local suctPIDIFactor = tonumber_def(get_gbl("suctPIDIFactor",0),0)

local suctPIDDFactor = tonumber_def(get_gbl("suctPIDDFactor",0),0)

local dischPIDPFactor = tonumber_def(get_gbl("dischPIDPFactor",0),0)

local dischPIDIFactor = tonumber_def(get_gbl("dischPIDIFactor",0),0)

local dischPIDDFactor = tonumber_def(get_gbl("dischPIDDFactor",0),0)

local recycleCtrl = false

local recycleSuctionRev = false

local recycleDischargeRev = false

if recycleChan > 0 and recycleTerm > 0 then

recycleCtrl = true

end

local dischPct = 100

local suctPct = 100

local dischOutput = 0

local suctOutput = 0

local rSuctOutput = 0

local rDischOutput = 0

local minLoad = 0

local maxLoad = 100

local minRecycle = 0

local maxRecycle = 100

local speedTarget = get_sGbl("speedTarget",0)

local recycleTarget = get_sGbl("recycleTarget",0)

function map_range(rangeLow,rangeHigh,input)

if input <= rangeLow and input <= rangeHigh then

return 0

end

if input >= rangeLow and input >= rangeHigh then

return 100

end

local rangeDiff = math.abs(rangeLow - rangeHigh)

local min = math.min(rangeLow,rangeHigh)

local retval = math.abs(input - min) / rangeDiff * 100

if retval > 100 then retval = 100 end

if retval < 0 then retval = 0 end

return retval

end

local suct = false

local suctVal = 0

if tonumber_def(get_gbl("spSuctEn",0),0) == 1 then

if suctTerm > 0 and suctChan > 0 then

suctVal = get_channel_val(suctTerm,suctChan)

suct = true

end

end

if suct then

if spSuctType == "linear" then

local suctDiff = suctSp - suctMin

if suctDiff == 0 then suctDiff = 1 end

if suctVal < suctSp then

local suctErr = suctSp - suctVal

suctPct = suctErr / suctDiff

if suctPct > 1 then suctPct = 1 end

if suctPct < 0 then suctPct = 0 end

suctOutput = (1 - suctPct) * 100

else

suctOutput = 100

end

else

set_gbl("PIDsuctEnable",1)

set_gbl("PIDsuctPFactor",suctPIDPFactor)

set_gbl("PIDsuctIFactor",suctPIDIFactor)

set_gbl("PIDsuctDFactor",suctPIDDFactor)

set_gbl("PIDsuctSp",suctSp)

set_gbl("PIDsuctDeadband",0.2)

local suctPidOutput = doPid("suct",suctVal)

suctOutput = suctPidOutput

end

else

suctOutput = 100

end

local disch = false

local dischVal = 0

if tonumber_def(get_gbl("spDischEn",0),0) == 1 then

if dischTerm > 0 and dischChan > 0 then

dischVal = get_channel_val(dischTerm,dischChan)

disch = true

end

end

if disch then

if spDischType == "linear" then

local dischDiff = dischMax - dischSp

if dischDiff == 0 then dischDiff = 1 end

if dischVal > dischSp then

local dischErr = dischVal - dischSp

dischPct = dischErr / dischDiff

if dischPct > 1 then dischPct = 1 end

if dischPct < 0 then dischPct = 0 end

dischOutput = (1 - dischPct) * 100

else

dischOutput = 100

end

else

set_gbl("PIDdischEnable",1)

set_gbl("PIDdischPFactor",dischPIDPFactor)

set_gbl("PIDdischIFactor",dischPIDIFactor)

set_gbl("PIDdischDFactor",dischPIDDFactor)

set_gbl("PIDdischSp",dischSp)

set_gbl("PIDdischRevAct",1)

set_gbl("PIDdischDeadband",0.2)

local dischPidOutput = doPid("disch",dischVal)

dischOutput = dischPidOutput

end

else

dischOutput = 100

end

local minOutput = 100

local winning = 0

if suctOutput < minOutput then

minOutput = suctOutput

winning = 1

end

if dischOutput < minOutput then

minOutput = dischOutput

winning = 2

end

if suctOutput == dischOutput then

winning = 0

end

if winning == 0 then

set_gbl("PIDsuctMax",100)

set_gbl("PIDdischMax",100)

end

if winning == 1 then

set_gbl("PIDdischMax",math.min(suctOutput + 2,100))

set_gbl("integraldisch",0)

set_gbl("lastErrdisch",0)

set_gbl("outputSumdisch",0)

set_gbl("PIDsuctMax",100)

end

if winning == 2 then

set_gbl("PIDsuctMax",math.min(dischOutput + 2,100))

set_gbl("integralsuct",0)

set_gbl("lastErrsuct",0)

set_gbl("outputSumsuct",0)

set_gbl("PIDdischMax",100)

end

local recycleMinOutput = minOutput

local manOutput = 0

--********************************************************************

local manMode = 0

local manTerm = tonumber_def(get_gbl("manTerm",0),0)

local manChan = tonumber_def(get_gbl("manChan",0),0)

if manTerm > 0 and manChan > 0 then

local manInput = get_channel_val(manTerm,manChan)

if manInput > 0.5 then

manMode = 0

set_sVirt("SpeedControl","Auto")

else

manMode = 1

set_sVirt("SpeedControl","Manual")

end

else

if get_sVirt("SpeedControl","Auto") == "Auto" then

manMode = 0

else

manMode = 1

end

end

--if manMode == 1 and get_state() == 8 then

local manSpeed = get_sVirt("ManualSpeed",0)

local idleSpeed = get_gbl("idleSpeed",0)

local lowSpeed = get_gbl("lowSpeed",0)

local highSpeed = get_gbl("highSpeed",0)

local maxSpeed = get_gbl("maxSpeed",0)

local diff = highSpeed - lowSpeed

if diff < 0 then diff = 0 end

local maxDiff = maxSpeed - idleSpeed

if maxDiff < 0 then maxDiff = 0 end

if get_sVirt("speedBump",0) ~= 0 then

local si = get_gbl("SpeedIncrement",0)

local sip = get_param("SpeedIncrement",0)

if sip ~= 0 then si = sip end

manSpeed = manSpeed + (si * get_sVirt("speedBump",0))

set_sVirt("speedBump",0)

end

if get_sVirt("AutoManBump",0) > 0 then

set_sVirt("SpeedControl","Auto")

set_sVirt("AutoManBump",0)

end

if get_sVirt("AutoManBump",0) < 0 then

set_sVirt("SpeedControl","Manual")

set_sVirt("AutoManBump",0)

end

if manMode == 1 then

local manSpeedTerm = tonumber_def(get_gbl("manSpeedTerm",0),0)

local manSpeedChan = tonumber_def(get_gbl("manSpeedChan",0),0)

if manSpeedTerm > 0 and manSpeedChan > 0 then --*** USE SPEED POT TO SET SPEED

local speedInput = tonumber(get_channel_val(manSpeedTerm,manSpeedChan))

local speedPct = (speedInput / 5) * 100

if speedPct > 100 then speedPct = 100 end

if speedPct < 0 then speedPct = 0 end

manOutput = speedPct

manSpeed = math.floor((speedPct / 100) * diff + lowSpeed + 0.5)

else -- Use ManualSpeed to set speed

manOutput = ((manSpeed - lowSpeed) / diff) * 100.0

if manOutput < 0 then manOutput = 0 end

if manOutput > 100 then manOutput = 100 end

end

minOutput = manOutput

else

--speedTarget =

local stRpm = (speedTarget/100) * maxDiff + idleSpeed

if stRpm < lowSpeed then stRpm = lowSpeed end

if stRpm > highSpeed then stRpm = highSpeed end

manSpeed = math.floor(stRpm)

end

if manSpeed < lowSpeed then

manSpeed = lowSpeed

end

if manSpeed > highSpeed then

manSpeed = highSpeed

end

set_sVirt("ManualSpeed",manSpeed)

--********************************************************************

local output1 = 0

local output2 = 0

if spSuctType == "pid" or spDischType == "pid" then

output1 = map_range(outputLow,outputHigh,minOutput)

set_sVirt("out1",output1)

output2 = map_range(outputLow2,outputHigh2,recycleMinOutput)

set_sVirt("out2",output2)

local hasRPM = idleSpeed > 0 and lowSpeed > 0 and highSpeed > 0 and maxSpeed > 0

if outputTerm and outputChan then

if hasRPM then

local speedRpm = output1 / 100 * (highSpeed - lowSpeed) + lowSpeed

speedTarget = (speedRpm - idleSpeed) / (maxSpeed - idleSpeed) * 100

else

speedTarget = output1

end

end

if recycleTerm and recycleChan then

set_ao_val(recycleTerm,recycleChan,output2)

end

if get_state() == 9 then

speedTarget = get_sGbl("speedTarget",0)

if speedTarget > 0 then speedTarget = speedTarget - rampRate1 end

if speedTarget < 0 then speedTarget = 0 end

end

if get_state() < 8 then speedTarget = 0 end

set_sGbl("speedTarget",speedTarget)

set_ao_val(outputTerm,outputChan,speedTarget)

set_sVirt("spTarget",speedTarget)

if hasRPM then

local sRpm = (speedTarget/100) * maxDiff + idleSpeed

set_sVirt("Speed Target",math.floor(sRpm + 0.5))

end

else

-- Remember that minOutput is 0 - 100 pct of lowSpeed <-> highSpeed

-- We need to convert this to 0 - 100 pct of idleSpeed <-> maxSpeed

local suctPct = map_range(outputLow,outputHigh,minOutput)

local speedRpm = suctPct / 100 * (highSpeed - lowSpeed) + lowSpeed

minOutput = (speedRpm - idleSpeed) / (maxSpeed - idleSpeed) * 100

if minOutput <= speedTarget then

speedTarget = speedTarget - rampRate1

if speedTarget < minOutput then speedTarget = minOutput end

else

speedTarget = speedTarget + rampRate1

if speedTarget > minOutput then speedTarget = minOutput end

if speedTarget > maxLoad then speedTarget = maxLoad end

end

if speedTarget > maxLoad then speedTarget = maxLoad end

if speedTarget < minLoad then speedTarget = minLoad end

if recycleCtrl then

local recyclePct = map_range(outputLow2,outputHigh2,recycleMinOutput)

if recyclePct <= recycleTarget then

recycleTarget = recycleTarget - rampRate2

if recycleTarget < recyclePct then recycleTarget = recyclePct end

else

recycleTarget = recycleTarget + rampRate2

if recycleTarget > recyclePct then recycleTarget = recyclePct end

end

if recycleTarget > maxRecycle then recycleTarget = maxRecycle end

if recycleTarget < minRecycle then recycleTarget = minRecycle end

local recycleOutput = recycleTarget

if get_state() < 8 then

recycleTarget = 0

end

if recycleRevAct == 1 then

recycleOutput = 100 - recycleOutput

end

set_ao_val(recycleTerm,recycleChan,recycleOutput)

set_sGbl("recycleTarget",recycleTarget)

set_sVirt("recycleTarget",recycleTarget)

end

if get_state() == 9 then

speedTarget = get_sGbl("speedTarget",0)

if speedTarget > 0 then speedTarget = speedTarget - rampRate1 end

if speedTarget < 0 then speedTarget = 0 end

end

if get_state() < 8 then speedTarget = 0 end

set_sGbl("speedTarget",speedTarget)

set_ao_val(outputTerm,outputChan,speedTarget)

set_sVirt("spTarget",speedTarget)

local sRpm = (speedTarget/100) * maxDiff + idleSpeed set_sVirt("Speed Target",math.floor(sRpm + 0.5))

end

Handling Special Characters in Strings

When scripting in Lua for the DE-4000 system, it is important to correctly handle special characters within strings to prevent errors. This is especially critical when passing strings to functions like Custom Fault and others.

Special Characters in Strings

Non-alphanumeric characters, such as %, “, and others, can cause issues in Lua if not properly escaped. Below are some common cases and their solutions.

- Escaping the % Character

- Issue: The % symbol is treated as a special character in Lua and needs to be escaped.

Solution: Use %% to represent a literal % in a string.

Example: Escaping %

local faultMessage = "Current value is 50%% over the limit."

custom_fault(faultMessage)

- In this example, %% ensures that the % is displayed as a literal percentage sign.

Best Practices for Strings with Special Characters

- Always escape non-alphanumeric characters when constructing strings for Lua functions.

- Review strings passed to critical functions like custom_fault or similar to ensure all special characters are properly escaped.

Summary

- Use %% for %, double quotes (“”) for “, and backslashes (\\) for \.

- Follow Lua’s conventions for escaping special characters to ensure robust script execution.

- Consider implementing automated escaping in custom functions to simplify user scripting efforts.