Introduction to Bi-Fuel Technology

The GTI Bi-Fuel System from Altronic offers an affordable and efficient means of operating industrial diesel engines utilizing both diesel and natural gas (or other available gas) as fuel sources. This innovative, patented system, which requires no modification to the internal components of the engine, allows for operation on natural gas up to a maximum of 70%* of the fuel required to maintain the desired speed and load. Reduced fuel costs and extended runtime are just a few of the benefits of Bi-Fuel operation.

The GTI Bi-Fuel System operates by blending both diesel fuel and natural gas in the combustion chamber. This is achieved using a fumigated gas-charge design, whereby natural gas is pre-mixed with engine intake-air and delivered to the combustion chamber via the air-intake valve. The air-gas mixture is ignited when the diesel injector sprays a reduced quantity of diesel fuel into the chamber.

This diesel “pilot” acts as the ignition source for the primary air-gas combustible mixture. Because the Bi-Fuel System utilizes the OEM air-intake and diesel injection systems, no internal engine modifications are required for installation.

Features

No engine

modifications required

No power or

efficiency losses

Low cost and easy

to install

Reduces operating

costs

Extends run-time of

standby engines

Lowers emissions

No high-pressure

gas supply

State-of-the-art

controls and monitoring

Major Bi-Fuel System

Components and Subsystems

Air-Fuel Mixer

The AGM-PV is a venturi carburetor that provides the optimal demand signal for use in supplying the required air/gas mixture to the engine. The proprietary design is manufactured to exacting tolerances from anodized aluminum for corrosion resistance and highly reliable service.

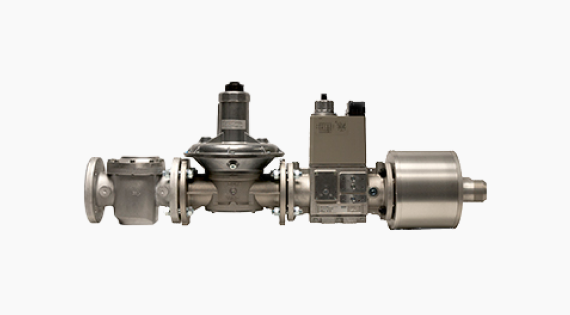

Standard Gas Train

Conditioning and regulating the natural gas prior to admission into the engine is a critical part of the GTI Bi-Fuel system. The system “gas train” includes a 50-micron fuel filter, a manual shutoff valve, an electrically operated solenoid valve actuated in the event of an emergency or for system shutdown, and a zero-pressure, demand-type gas pressure regulator.

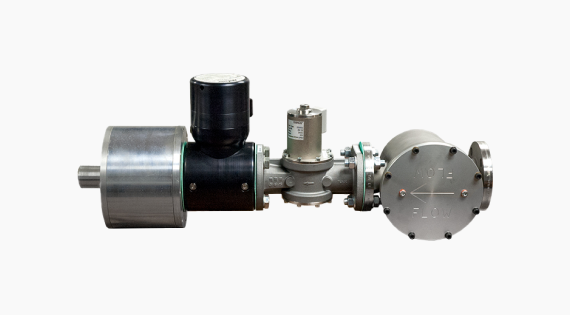

GTI+ Gas Train

The GTI+ system utilizes a fully electronic, advanced gas train design, which includes the Altronic AGV5 Fuel Valve, a microprocessor-based smart valve equipped with a fast-acting voice coil for rapid and accurate response.

Control Panels

The Control Panels are based on proven Altronic controllers and provide state-of-the-art engine control and safety shutdown monitoring. The system is designed specifically for GTI Bi-Fuel applications and is straight-forward and easy to operate.

GTI Bi-Fuel® System Project Overview:

Zenergy

Alternative Fuel Systems In North Dakota, the demand for electricity to operate new oil well drilling sites is overwhelming. The number of new wells averages 160 per month and in most cases the wait for electric service is 8 to 12 months. ECO/AFS has outfitted several rental generators with Bi-Fuel® systems. These generators are operating on 60% well gas and 40% diesel. Jim Fehlauer, Field Superintendent for Zenergy, had this to say about the GTI Bi-Fuel® system, “Thanks to Industrial Equipment Sales and Service and ECO/AFS for providing Zenergy with quality equipment and (Left to right) Jeff Anderson (ECO Alternative Fuels Systems) Jim Fehlauer (Zenergy) Sam Osborne (Arrow Pipeline LLC) quality service. This combination has allowed Zenergy to get our wells on line and producing while we wait for electricity. We had seven GTI Bi-Fuel® generators running 24/7 for 8 months with zero down time…which really helps our bottom line.”

Fehlauer concluded, “Though we have not needed it, we appreciate the f lexibility of using both fuels. If well gas is interrupted the engine switches to straight diesel without a hitch. This helps us to avoid costly down time.”

I highly recommend the GTI Bi-Fuel® system. Zenergy is currently running twelve units, and I will not use anything else.

Savings

The savings realized by running the GTI Bi-Fuel System is directly related to the cost of diesel fuel, cost of gas, and the number of hours of operation. The following is an example is a cost comparison between running a 1000 kW generator on 100% diesel and on Bi-Fuel with a 65% gas-to-diesel ratio in continuous operation. A number of assumptions are made in this example which are clearly stated in order to clarify the calculations.

FACTS AND ASSUMPTIONS

| Fuel consumption @ 1000 kW: | 54 gph (100% diesel) |

|---|---|

| Hours per year | 8000 |

| Gas/Diesel ratio | 65% |

| Diesel cost ($/gal) | $3.50 per gallon |

| Natural gas cost ($/mcf) | $11.00 per mcf |

| hhv of #2 diesel | 140,000 btu/gal |

| hhv of natural gas | 1,000 btu/scf |

| Gas Equivalent Gallon (GEG) | 140 scf/gal |

100% DIESEL OPERATION

| Diesel use per hour | 54 gallons |

|---|---|

| Diesel cost per hour | $189.00 (54 x $3.50) |

| Diesel cost per year | $1,512,000 ($189 x 8000) |

BI-FUEL OPERATION

| Diesel use per hour | 18.9 gph (54 x 0.35) |

|---|---|

| Diesel cost per hour | $66.15 (18.9 x $3.50) |

| Gas use per hour | 4914 scf (54 x 0.65 x 140) |

| Gas cost per hour | $54.05 (4914/1000 x $11.00) |

| Total fuel cost per hour | $120.20 ($66.15 + $54.05) |

SAVINGS

| Bi-Fuel Savings per Hour | $68.80 ($189.00 -$120.20) |

|---|---|

| Bi-Fuel Savings per 8000 hours | $550,368.00 ($68.90 x 8000) |

Bi-Fuel System FAQs

Information Request

& Estimate

Fill it out completely, then click the “Print” button. Save and rename the file, then return it as an email attachment to: sales.altronic.gti@hoerbiger.com.

A GTI representative will respond to you as soon as possible.

Thank you for your interest in GTI Bi-Fuel®.