Bi-Fuel Operation & Installation

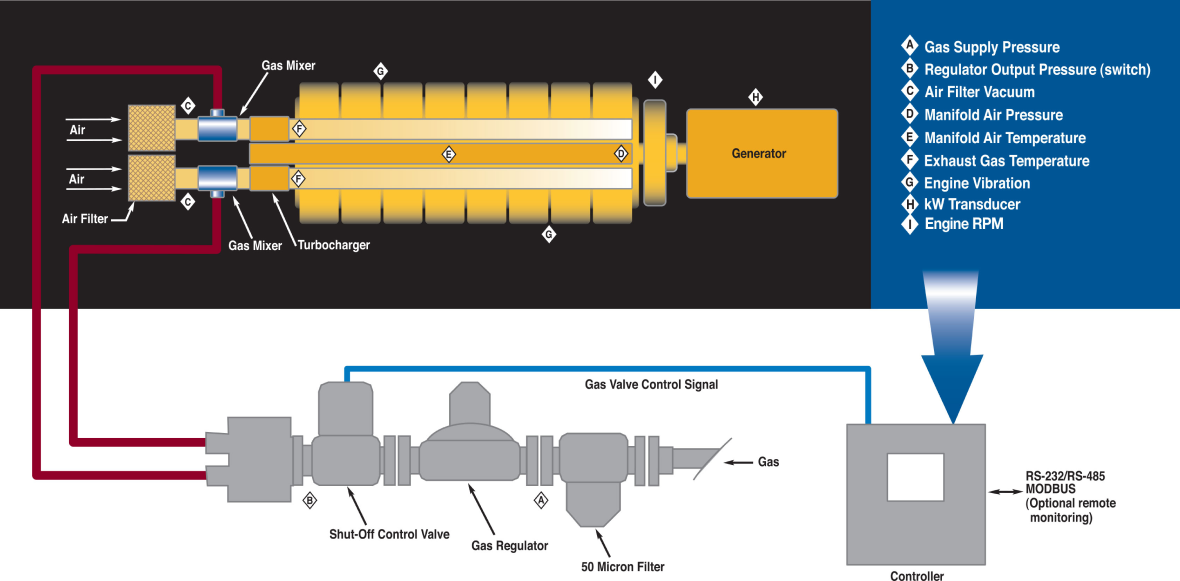

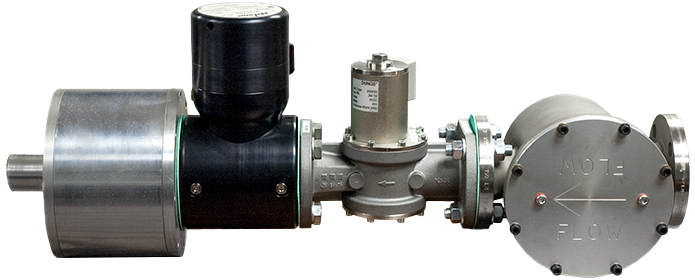

The GTI Bi-Fuel System provides gas to the engine using a technique known as fumigation. In a process similar to that utilized by carburetors found in spark engine applications, the system supplies gas to the engine using the original air intake system. In the typical configuration, the gas is introduced at a location upstream of the turbocharger and downstream of the engine air cleaner. The gas is introduced at approximately atmospheric pressure using a proprietary air-fuel mixing device that allows for a high level of fuel atomization with the smallest possible air restriction.

After exiting the mixer, the fuel-air charge is compressed in the turbo and then distributed to each cylinder by the engine air-intake manifold. The intake valves deliver the mixture to individual cylinders at the proper moment according to the normal valve timing of the engine. Upon entering the combustion chamber, the air-gas mix is compressed during the compression stroke and ignited when the diesel injector is activated.

Because a majority of the fuel and air is already pre-mixed prior to activation of the injector, the combustion differs slightly from the normal “stratified charge” process of the diesel engine. During bi-fuel operation, the combustion is slightly accelerated and the pressure rise in the cylinder is slightly “steeper” than normal diesel combustion. Peak cylinder pressures reached during bi-fuel

operation, however, are within normal limits. Although natural gas has a lower energy density than diesel fuel, the lean-burn/excess air operation of the diesel engine com-bined with the compression provided by the turbocharger, allow the system to supply adequate quantities of natural gas to the combustion chamber, therefore assuring that the equivalent power can be realized.

All OEM engine specifications for injection timing, valve timing, compression ratio, etc., remain unchanged after installation of the Bi-Fuel System, and no engine modifications are required.

The included control system monitors various engine parameters (depending on engine size and application) such as manifold air pressure (boost pressure), exhaust gas temperature, intake manifold air temperature, inlet air restriction, supply gas pressure and engine vibration. This data allows the system (see inset) to determine when to activate or deactivate bi-fuel operation depending on load level, ambient conditions, knock limits, low or high gas pressure or a detected malfunction in the engine. The automatic default mode is always to 100% diesel operation.

Performance

Installation of a Bi-Fuel System in no way compromises the performance of the generator relative to the rated load of the machine. A generator with a 1000 kW stand-by rating which has been retrofitted to the GTI Bi-Fuel System will still provide 1000 kW of power in both 100% diesel and bi-fuel modes. In other words, the generator is not de-rated after installation of the Bi-Fuel System. Similarly, there is no decrease in generator load response or stability while operating in either fuel mode.

After installation of the GTI Bi-Fuel System hardware, the generator is then operated under various load settings (normally with the use of a resistive load bank) while the System is checked and calibrated. After this “tune-in” process is completed, the generator is fully tested in bi-fuel mode to assure proper operation of the GTI Bi-Fuel System and generator during light, medium, heavy and transient loads. Finally, the generator is tested in 100% diesel mode to verify that its 100% diesel performance has not been affected by installation of the GTI Bi-Fuel System.

Bi-Fuel Retrofit Kits

| GTI Series | Engine Power Rating | Engine Type | Panel Option | Vibration Sensor(s) | CSA Certified1 |

|---|---|---|---|---|---|

| 252 | Up to 300 kWe | Single Turbo, Single Cooler | GPN0100-12 | Up to 8 | No |

| GPN1000-12 | |||||

| 50 | 301-800 kWe | Single Turbo, Single Cooler | GPN1000 | Up to 8 | Yes |

| Up to Six Turbo, Four Cooler | GPN20XX | Standard (2) | |||

| 65 | 801-1500 kWe | Single Turbo, Single Cooler | GPN1000 | Up to 8 | Yes |

| Up to Six Turbo, Four Cooler | GPN20XX | Standard (2) | |||

| 80 | 1501-2500 kWe | Single Turbo, Single Cooler | GPN1000 | Up to 8 | Yes |

| Up to Six Turbo, Four Cooler | GPN20XX | Standard (2) | |||

| GTI+ | Up to 4MW+ 3 | Up to Six Turbo, Four Cooler | GPN2020 | Standard (2) | Yes |

| GPN2030 | |||||

- CSA Certified Class I, Div. 2, Group D System available. Contact a GTI Authorized Distributor for details.

- Series 25 kits require 12Vdc Power; all other Series require 24Vdc power. Not to be used on generator paralleling applications.

- Contact your GTI Authorized Distributor for larger applications.

For generator paralleling applications up to 300kW use the series 50 gas train.

CARB compliant configuration kits available up to 3MW.

Safety

The patented GTI Bi-Fuel System incorporates a sophisticated, electronic control system, which controls both natural gas and diesel fuel during operation. In addition, the GTI Electronic Control System (ECS) acts as an engine safety device, by monitoring up to 31 critical data channels including:

Gas Supply

Engine Vacuum

Intake Manifold Air Pressure

Exhaust Gas Temperature

Engine Vibration

Engine RPM

The various data channels are displayed on the ECS via an LCD display in either text or graphical format. The ECS notifies the user locally (via an LED general fault light) or remotely via modem, in the event of a fault.

If a fault is detected, the ECS will automatically switch bi-fuel off, allowing 100% diesel operation, and data-log the fault. The ECS fault set points are field adjustable and allow installation technicians to customize the Bi-Fuel System to the specific requirements of the customer and/or the operational limitations set-forth the engine manufacturer. Once programmed, the fault settings are protected by a keypad lockout code, which prevents unauthorized personnel from altering the set points.

The ECS guarantees that in the unlikely event of either a Bi-Fuel System malfunction, or a disruption in natural gas supply pressure (either low or high pressure faults), the diesel engine will be protected from damage. Most of the monitored channels are latching type faults, i.e. if the Bi-Fuel System is deactivated by the ECS, the generator cannot be returned to Bi-Fuel operation until the ECS panel is manually reset.

Lastly, the ECS also incorporates a built-in time delay function, which prevents initiation of Bi-Fuel operation after generator start-up, for a period of up to 999 seconds. This feature is used when the converted generator is used in paralleling operations, and allows the generator to start-up and synchronize on 100% diesel fuel before automatically switching to bi-fuel operation.