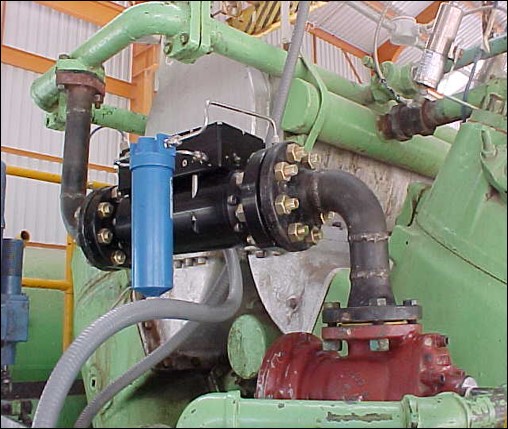

The GOV10/50 series is both a fuel valve and electronic governor integrated into a single unit. These governors fit a wide range of fuel injected engines including integral types such as Cooper Bessemer, Clark, Ingersoll Rand and Worthington, and separable types such as White Superior and MEP. The GOV10 model is used on engines up to approximately 3,500 hp, whereas the GOV50 applies to engines from 3,500 to 10,000 hp. The GOV series completely eliminate troublesome hydraulic governors, actuators, and linkages, and significantly improve starting performance and speed stability. The GOV series may also be ordered with a fuel flow measurement option utilizing a built-in orifice meter and built-in pressure, differential pressure, and temperature sensors. Utilizing fuel flow and fuel flow/ revolution values, maximum engine horsepower and maximum engine torque limits can be applied for improved engine/compressor safety. A sophisticated engine start-up and governing algorithm is resident in the GOV10/50 units allowing their use in conjunction with a PLC or simply as a stand-alone replacement governor. All configuration of control parameters, timers and setpoints is accomplished through the GOV Display Module. The complete governor system consists of the GOV10 or 50 unit, a speed-sensing magnetic pickup, and the Display Module, a small computer-based terminal that serves as a display and configuration device. Internal construction and operation of the GOV series governors is explained on the inside pages

Integral electronics and state-of-the-art fuel valve

Eliminates separate actuators and linkages

Improved starting — sets gas pressure to pre-selected value and ramp rate

Better speed stability — continuous dynamic gain adjustment for load and no load conditions

Fail safe design — spring-loaded poppet valve closes on loss of power or gas pressure

Total fuel flow and fuel flow/revolution displayed and outputted as analog and serial signals

Serial communication of all critical data in modbus rtu

High tolerance to dirt — flow-through design minimizes effects of contamination

CSA-certified for Class I, Divisions 1 and 2, Group D hazardous areas