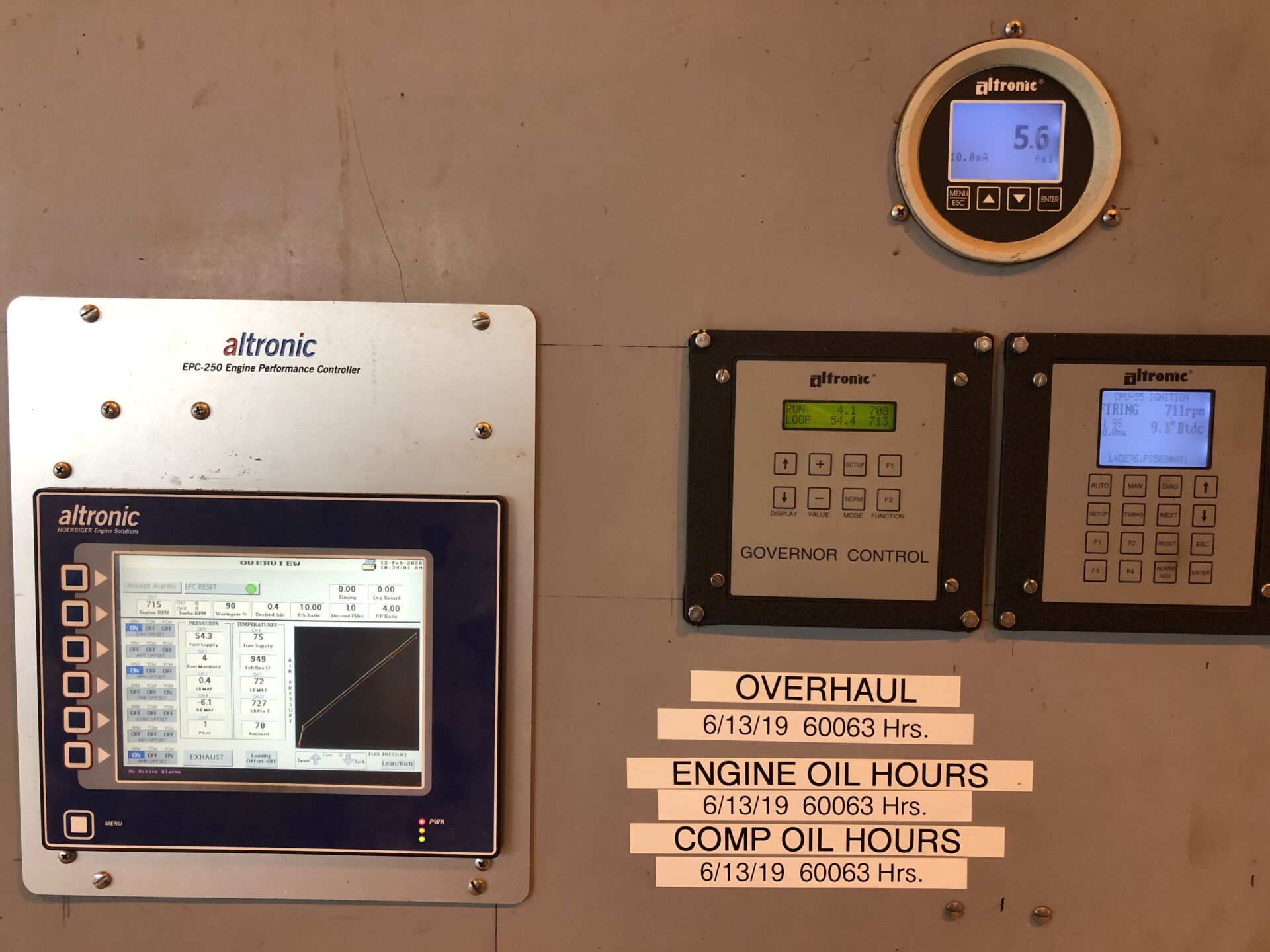

The Altronic Controls EPC-250 Engine Performance Controller is designed to provide continually optimized control of air/fuel ratio and ignition timing on large, fuel-admitted integral and separable compressor packages. Incorporating an 8.4" MIDAS HMI and a purpose-built Altronic control module, the EPC-250 easily and effectively replaces both traditional pneumatic controls and legacy electronic control systems, and is also a drop-in replacement for the Altronic EPC-200. A user-defined RPM map is used as the primary control for the 4-20mA ignition timing output. Engine air/fuel ratio is most often controlled by exhaust by-pass versus an on-board 4-20mA output mapped to engine fuel pressure. Other controller inputs, including air manifold temperature, air manifold pressure, and fuel BTU quality can be used as biasing factors for either/ both control maps to provide an enhanced level of control and optimization across a wide range of engine makes, models, and application requirements. Two digital offsets are also available to account for load and detonation-related events. In addition to air/fuel ratio and timing functions, the EPC-250 also provides six user-programmable, solid-state relay outputs to support common start/stop requirements including purge, crank, crank-disconnect, etc. A seventh discrete output provides a signal to a safety shutdown monitoring system in the event of an overspeed, overload, or on a loss of any system input. The EPC-250 is easily configured via the system keypad and a user-friendly menu system. Full Modbus RTU TCP/IP communications are integrated into the system to allow for simple integration with other process control, monitoring, or telemetry systems.

Optimizes engine performance and efficiency

Provides precise control of the engine air/fuel ratio and ignition timing

Ideal for retrofit of existing electronic or pneumatic controls on large, integral compressor engines including CooperBessemer®, Clark®, Worthington®, Ingersoll-Rand® or fuel-admitted separable compressor packages Superior® (including Endyn® models), MEP®, and others

Simple user configuration and adjustability from the 8.4″ LCD/touch screen

Incorporates trending, datalogging, and remote operation

Drop-in replacement/upgrade for all existing Altronic EPC200 systems

Supports RS-485/232 and 10/100 Ethernet communications

System components fully CSA certified for use in Class I, Division 2, Groups C&D hazardous areas