Magnetic pickups convert mechanical motion into electrical energy without mechanical linkage or external power. These transducers sense any ferromagnetic material having discontinuities, such as gear teeth or slots, and generate an AC Voltage. The frequency of this voltage is equal to the number of discontinuities passing the pickup and is proportional to RPM when the pickup is mounted in proximity to the teeth of a gear on a rotating shaft.

See the Magnetic Pick-up brochure for the following information.

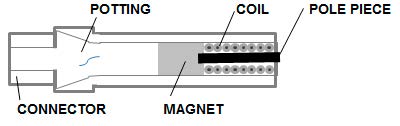

- Figure 1 shows the typical construction of a MPU. The pole piece forms a magnetic path from the magnet , creating an external magnetic field in front of the sensor. When this magnetic field is disrupted by a ferromagnetic material an AC voltage is induced in the coil. Altronic, LLC – A Member of the HOERBIGER Group

- Figure 2 shows output voltage as a function of surface speed. Note: The Altronic intrinsically-safe MPU has internal voltage-limiting zener diodes. The output will never exceed 18V (p-p) regardless of speed. The AC output voltage is inversely proportional to the clearance between the pole piece and the gear. In many applications a 0.010 to 0.020 inch gap is adequate; however, if slow surface speed or maximum output is required, the gap should be as small as practical (0.005 inches or less). The amplitude of the output voltage depends on the surface speed of the gear, the gap between the pole piece and the gear, the gear tooth size and spacing, and the load impedance. The pickup output voltage is directly proportional to surface speed of the gear. Surface speed is most often expressed in terms of inches per second.