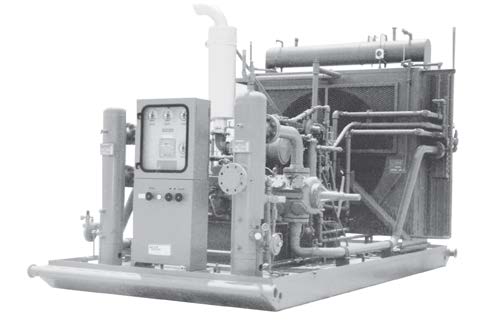

The DE-1550 Small Engine & Compressor Package Monitoring System uses state-of-the-art microcontrollers and surfacemount PCB assembly technology to provide users of compressors and other critical rotating equipment with a sophisticated, yet reliable, means of protecting and controlling both the prime mover and the load machine (compressor, pump, etc.). The base DE-1550 configuration offers a number of digital and analog outputs, as well as twenty (20) inputs that can be individually configured for use with switch contacts, analog transducers and up to 12 of the inputs can be configured for J or K thermocouples. This approach also allows for a single control system to be used across a fleet of units, thus simplifying maintenance and part stocking requirements, along with system training requirements for operating personnel.

- State-of-the-art control system specifically designed to protect, monitor and control critical rotating machinery, such as engine or motor-driven compressors, pumps and generators operating in harsh/hazardous areas

- Built-in linear speed control allows for linear suction pressure vs engine speed control

- Integrated rich-burn engine air/fuel ratio control to support effective emissions management strategies

- Selectable number of auto-start attempts. Safety warning and countdown timer visible on the enhanced display between start attempts.

- System inputs can be individually configured for: — Sensor Type: Analog transducer input, thermocouple input (type J or K) or digital (switch) input — Sensor Class: Class A, B or C logic — Digital Input Sensor Run/Fault Status: Normally-open or Normally-closed

- Large color-changing display offers optimal annunciation of all functions.

- ModBus-RTU compatible, and easily configurable via included WindowsTM-based terminal program Integrated AFR Control